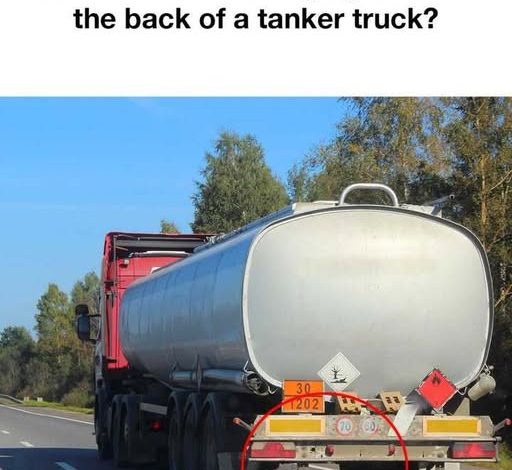

Never realized this!!!

Most people hardly notice it—just a small metal chain dangling from the back of a tanker truck. But that seemingly insignificant detail plays a critical role in transportation safety, quietly protecting lives and infrastructure every day.

Tanker trucks are specially engineered to carry hazardous or flammable liquids such as fuel, oil, or industrial chemicals. With such high-stakes cargo, every safety measure matters. One of the simplest and most crucial features of these massive vehicles is the grounding chain. Though easily overlooked, this humble component has a remarkable purpose: preventing static electricity from causing dangerous explosions.

As a tanker rolls down the road, its metal parts generate friction against the air and road surface. At the same time, the liquid contents inside slosh and churn. This movement builds up static electricity—especially when the cargo is flammable. Without proper grounding, a single spark from this buildup could ignite the contents and result in catastrophe. That’s where the grounding chain comes in. By dragging along the ground, the chain continuously discharges static into the earth, keeping the vehicle safe and neutral.

The grounding chain acts like a safety valve for static electricity. It’s inexpensive, reliable, and surprisingly effective. Over the decades, this tiny feature has saved countless lives, often without anyone realizing it. Its importance became widely recognized after multiple incidents in the mid-20th century, where fires and explosions were traced back to uncontrolled static discharges. Regulators took notice, and grounding became mandatory.

Today, the U.S. Department of Transportation and global transportation agencies require grounding systems on fuel and chemical transport vehicles. While modern solutions like anti-static additives and retractable reels are being developed, none have entirely replaced the chain. Its simplicity ensures durability, and its constant ground contact remains unmatched in reliability.

Yet, many people still mistake the chain’s purpose. Some believe it helps stabilize the vehicle or that it’s outdated and obsolete. In reality, it’s an essential safety mechanism that even advanced technology hasn’t rendered unnecessary. The chain is not decorative. It’s not optional. And it’s not just “old school.” It’s a frontline defense against disaster.

Maintenance is critical. Drivers and technicians must regularly inspect the chain for signs of wear, corrosion, or detachment. If the chain breaks or loses contact with the road, the risk of static buildup returns. Something as simple as a worn link or missing bolt can compromise the system and put lives at risk. That’s why routine checks are part of every serious inspection for fuel haulers.

As the transportation industry evolves with digital systems and automated safety protocols, some things remain unchanged for good reason. The grounding chain stands as a reminder that sometimes, the simplest tools are the most effective. It’s not flashy. It doesn’t require a microchip. It just works—day in and day out—silently protecting everything around it.

So next time you see a tanker truck pass by, take a moment to notice the chain beneath it. It may not look impressive, but it could very well be the reason you’ve never seen a fuel truck go up in flames.

In a world increasingly obsessed with high-tech solutions, the grounding chain is proof that humble, practical engineering still has a place. It’s a small thing with enormous impact—literally the grounding force behind the safe transport of the world’s most volatile materials.